Production Update

/Exciting times, everything is coming together nicely; it seems we’re on the home stretch now!

Last month we received the re-powder coated and silk screened faceplates from American Metal Specialties which did not pass our initial QA (~35% of the order) and now have all the front panels for the run. While the high error rate from the first go was frustrating, we were very impressed with AMS’s commitment to quality and their willingness not only to rectify the errors, but also offer to collaboratively develop a plan for their printers to ensure the next run goes smoothly.

The DATA's production test build

In mid-May we received the final revisions of the DATA’s circuit boards and now we are just about through with testing them; everything fits together beautifully and is working as designed! We were waiting for these boards rather anxiously, as there were a number of design changes. Most critical was the display’s 50 pin connector; mechanical tolerances were tight, but as you can see from the image, everything fits together perfectly, with a new edge profile cut that allows the display’s flexible “tail” to wrap around the front control board and meet with its connector on the rear board. We just finished up testing the SD Card sub-system last week and have just a few more tests to complete with the I/O scaling. At this point we’re fairly certain no further PCB revisions will be required before ordering the production’s panelized boards, which we hope to do by the end of next week.

New display mounting with PCB edge cut

We met with Josh and Lars at Darkplace Manufacturing the last week. The meeting was good and it seems there will be no trouble getting the DATA's SMD population completed quickly at their facility. The entire run is estimated to take only a few days to populate with Darkplace’s awesome pick n’ place machine, though it will take a few weeks to get the stencils and PCBs in prior to starting population. We can’t wait to see that machine in action; we’ll try to capture some video to share with you!

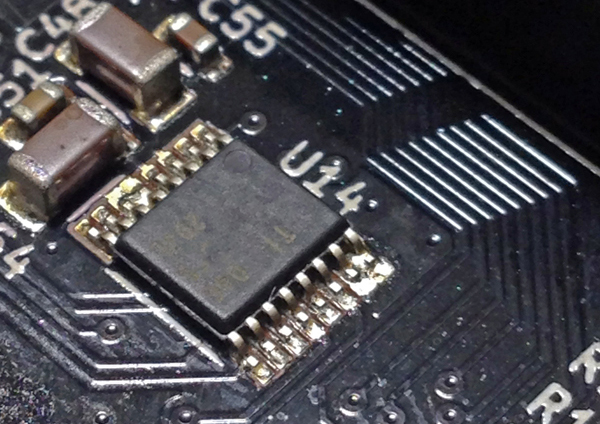

One little chip = 4 channels of 16-bit hi-res control voltage goodness

Lastly, in the previous production update we had mentioned that we did “a bit of feature creeping” on the DATA back in January, which lead to re-visiting the circuitry design, and ultimately to our “extended” production period. We upgraded the power system, added an internal signal routing matrix for run-time calibration, added additional signal scaling, and made a host of other tweaks. But the biggest addition we made was giving the DATA a new digital-to-analog converter (DAC); we replaced the DATA’s original 2 channel 12-bit DAC with a high-end 4 channel 16-bit DAC. So now the DATA is capable of outputting 4 streams of precision CV, or 4 trigger/gate signals, from any of it’s output jacks. We haven’t worked these extras into the current function's code just yet, but as you can imagine, we have plans for all this CV power!

Our reasoning behind these additions was to deliver a better product, with more capability and a longer life cycle (e.i., we don’t plan to make a DATA mk2 anytime soon). We hope you’ll agree it’s worth the extra effort and time.